A-JOINT® PRO is a water-permeable, frost and de-icing salt resistant paving joint mortar, which is particularly suitable for narrow and extra wide joints due to its self-compacting properties and high flowability.

A-JOINT® PRO prevents weed growth in the joints and is designed for traffic loads up to 12 tons. It is applicable to almost all natural stone and concrete block pavements in new construction and renovation.

A-JOINT® PRO minimizes maintenance and accident hazards while beautifying urban parks, pedestrian areas and public squares as well as private patios, walkways and traffic paths, pool and pond surrounds.

neutral

stone grey

basalt

Properties

- Sustainable, self-compacting and fast jointing solution

- Prevent Weed and abrasion-resistant

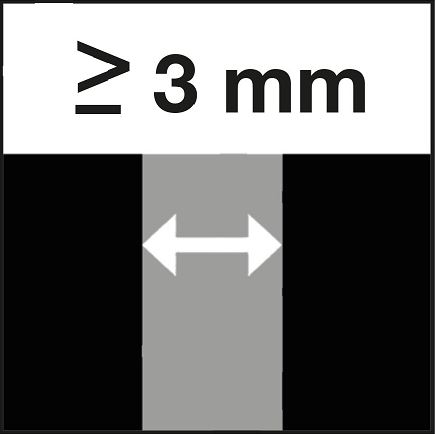

- For joint widths from 3 mm

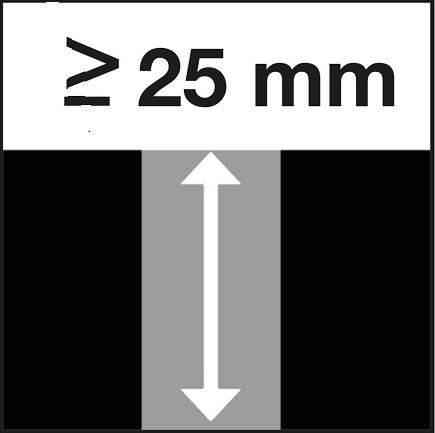

- For joint depths from 25 mm

- workable in drizzle and soil temperature from 0°C

- Fast traffic release up to use category N3

Consumption calculator

Processing instructions:

Preparing the site

The joints must be cleaned of weeds, roots and loose parts without leaving any residue and cleared to a depth of at least 25 mm (2/3 of the stone height for traffic load). The surface to be grouted must be freed from all dirt. Adjacent areas that are not to be grouted should be masked or covered.To avoid settling and loose stones, we recommend a permanently water-permeable and load-bearing substrate corresponding to the subsequent load (pay attention to the current standards and guidelines). We generally recommend the bonded construction method.

Pre-wetting:

Thoroughly pre-wet the entire surface. Higher floor temperatures and absorbent, open-pored stone require more intensive pre-wetting. Generally, clean and cold water should be used.

Mixing bucket:

Open the bucket. Pour the bottle inside completely to the sand component. Fill the emptied bottle to ¼ = 0.25 litres of water and close it, shake vigorously and add to the mixture. Make sure the bottle is completely empty. Use a professional stirring or mixing device. Start mixing process and mix thoroughly for at least 6 minutes until a creamy, flowing mass is obtained. No further addition of water is necessary.

Mixing bagged goods:

Open the bag and pour the sand into a suitable mixing container. Completely add the contents of the separately supplied bottle containers. Fill the emptied bottles with 0.5 litres of water each and close them, shake vigorously and add to the mixture. Ensure that the bottles are completely empty. Use a professional stirrer or mixer. Start the mixing process. After 3 minutes mixing time, add a further 2.5 litres of water and mix thoroughly for another 3 minutes until a creamy, flowing mixture is obtained.

Filling the joints:

Pour the finished mixture onto the pre-wetted surface. Work in the joint compound carefully and as diagonally as possible to the joint using a rubber squeegee. To optimise the flowability, we recommend dividing the mixture into two to three portions. Mix the remaining joint compound again briefly. Keep the surface constantly wet during this work.

Cleaning the surface:

After approx. 10-20 minutes, sweep the stone surface carefully and diagonally to the joint, using a medium-coarse street broom. If white gel-like streaks form on the stone surface, the correct sweeping time has not yet been reached. Then remove the remaining mortar residues with a fine coir broom. Swept-off material is not to be used again. Make sure that chamfers (beveling of the side edges) on slabs and pavers must be exposed.

Follow-up treatment:

Protect the freshly grouted surface from rain for 12-24 hours. We recommend using construction foil or tarpaulins as rain protection. To allow sufficient air to circulate, the rain protection must not be placed directly on the surface. At temperatures around 20°C, the surface can be walked on after 24 hours and driven on after 3 days. A strength test is recommended before use. Cleaning work (high-pressure cleaner max. 120 bar, min. 20 cm distance) may be carried out after 7 days at the earliest.

Important

Resin film: After grouting with A-JOINT® PRO, a thin resin film remains on the stone surface, which intensifies the stone colour and protects the stone from dirt. This resin film usually disappears over time due to weathering and use of the surface. If in doubt, create a small test area. The synthetic resin film is not a design defect, as neither the quality nor the functionality of the joint is affected.

Application notes: Use A-Joint ® Pro only with a stable, load-bearing and permanently water-permeable substructure or a slope of at least 2%. The application is only recommended in well ventilated areas. Please wear adequate protective clothing. Tools should be cleaned with water during and after application.

Regularly remove dirt, leaves and moss from the joint surface.

All fillers are natural products and are subject to natural colour variations. Our information is based on years of experience and the current state of the art, but is non-binding and does not constitute a contractual legal relationship.